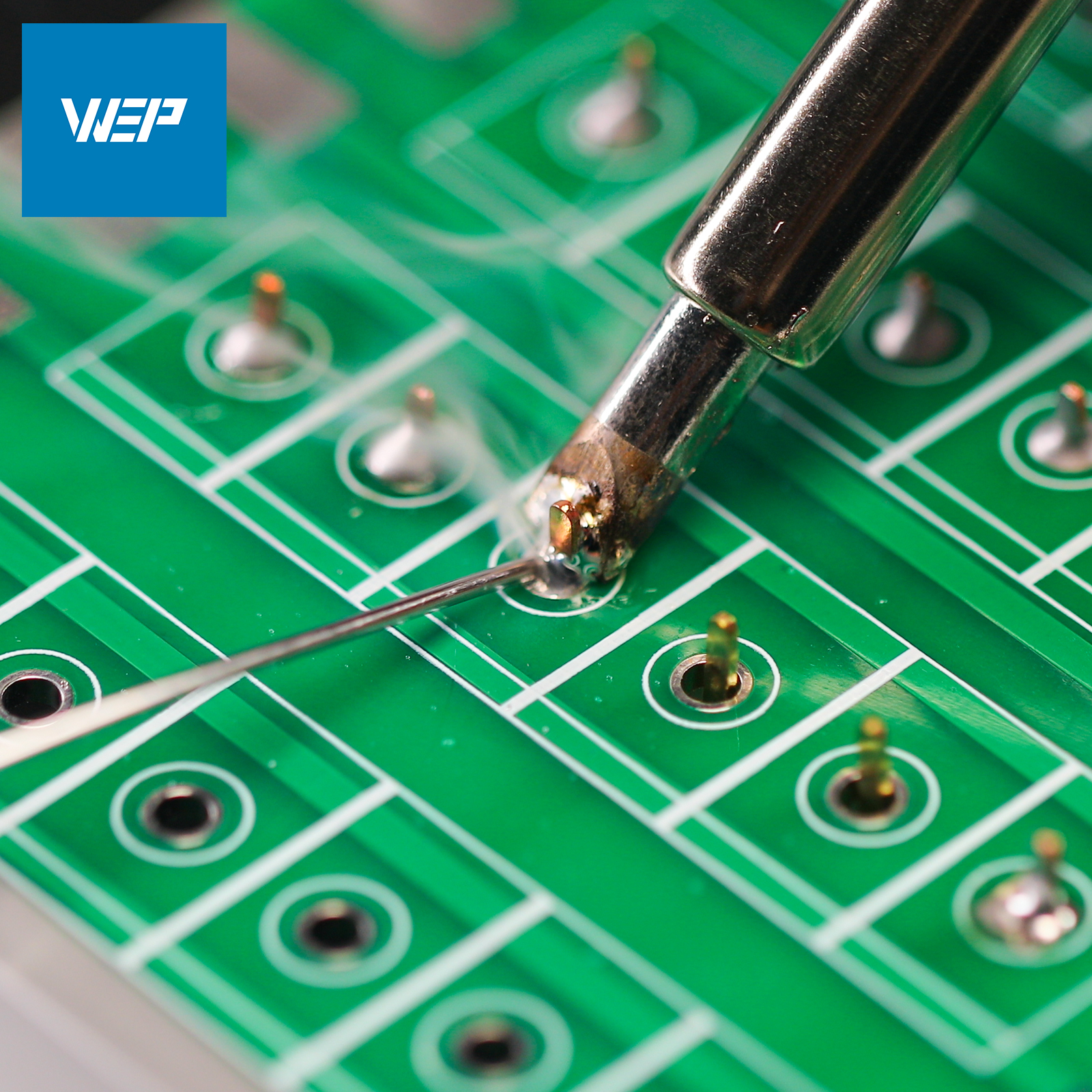

Make Your Soldering Tip Last Twice as Long.

Nov 02,2022 | WEP Tools

Most soldering tips are made of solid copper core, plated with a layer of iron, nickel, and chrome. The plating can wear easily when not used or maintained correctly, significantly reducing the intended lifespan of the soldering tip.

Don’t worry, here’s how we can make the tips last twice as long:

- Apply solder to the soldering tip as the soldering iron is heating up.

- Apply solder to the soldering tip after cleaning the tip.

- Apply solder to the soldering tip after use.

The general rule of thumb is to keep the tip coated with a layer of solder at all times to protect the plating underneath. This applies to all operating conditions when soldering, especially when using the iron at higher temperature settings. Because the plating oxidizes rapidly at a higher temperature setting, a brand-new uncoated soldering tip could be rendered useless in just 2 minutes when set to 896°F / 480°C.

In conclusion, the layer of solder can protect the soldering tip’s plating from oxidation, thus making the tip’s lifespan longer. This is definitely #1 on our soldering to-do to keep our soldering work cost-effective.